Manufacturers use a variety of interpolation techniques to substitute the over-range values in attenuation profiles.

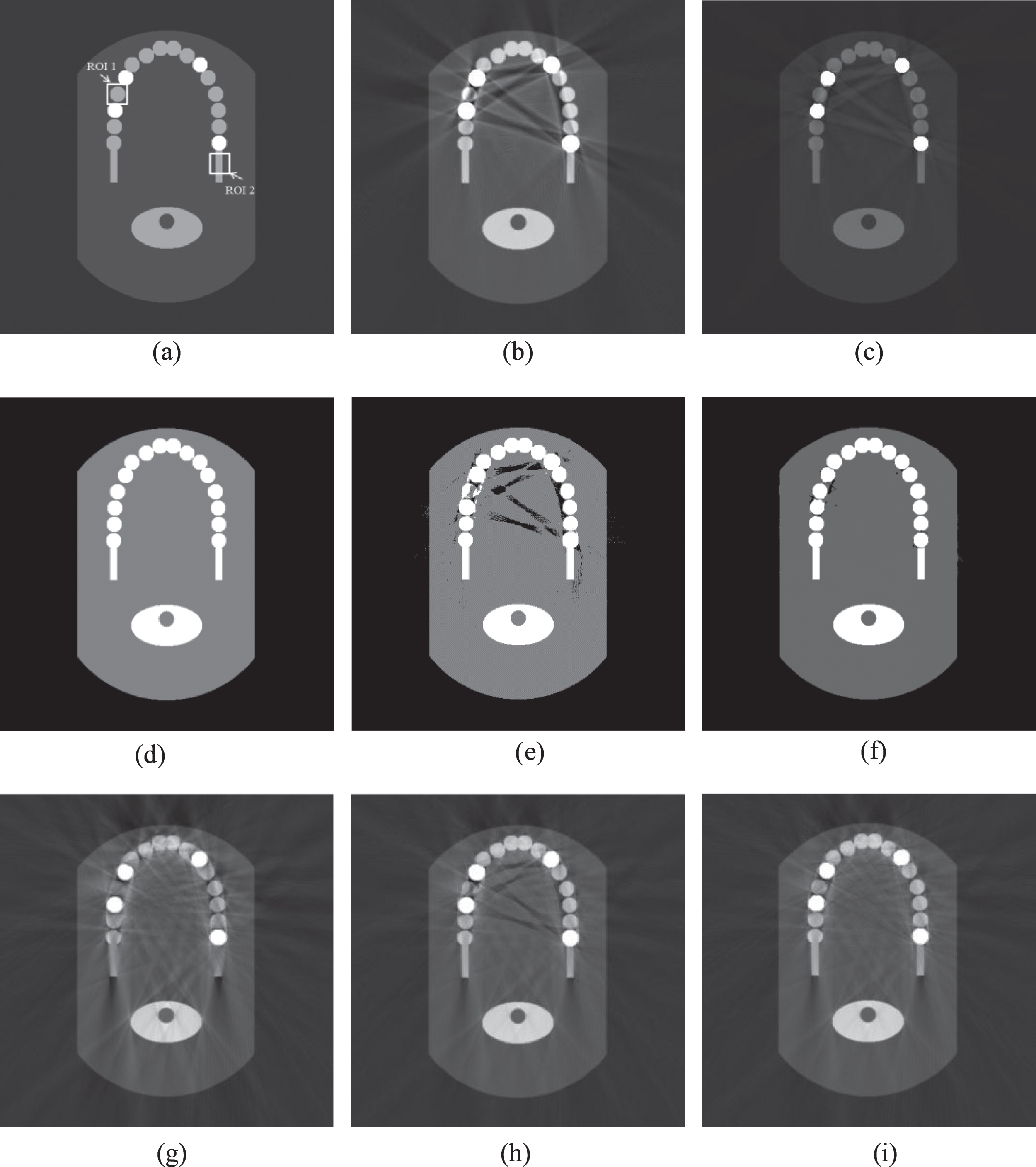

BEAM HARDENING ARTIFACT MEANING SOFTWARE

Streaking caused by over-ranging can be greatly reduced by means of special software corrections. When it is impossible to scan the required anatomy without including metal objects, increasing technique, especially kilovoltage, may help penetrate some objects, and using thin sections will reduce the contribution due to partial volume artifact. For non-removable items, such as dental fillings, prosthetic devices, and surgical clips, it is sometimes possible to use gantry angulation to exclude the metal inserts from scans of nearby anatomy. Patients are normally asked to take off removable metal objects such as jewelry before scanning commences. Additional artifacts due to beam hardening, partial volume, and aliasing are likely to compound the problem when scanning very dense objects. They occur because the density of the metal is beyond the normal range that can be handled by the computer, resulting in incomplete attenuation profiles. Metal ArtefactsThe presence of metal objects in the scan field can lead to severe streaking artifacts. The artefact occurs because the high density anatomy absorbs the lower energy photons while the higher energy photons pass through to the detectors which results in the beam becoming 'harder'. © 2020 American Association of Physicists in Medicine.Beam Hardening Artefacts Beam hardening artefacts appear as streaks and shadows adjacent to areas of high density such as the petrous bones, shoulders, and hips. Talbot-Lau beam hardening grating interferometry image quality phase contrast ring artifacts. The method depends on calibrations that can be performed on any system and does not require detailed knowledge of the x-ray spectrum, detector energy response, grating attenuation properties and imperfections, or the geometry and composition of the imaged object. The described method, which was developed to remove artifacts in absorption, phase, and normalized visibility micro-CT images due to beam hardening in the system gratings and imaged object, reduced the MSE by up to 96%. When the water calibration coefficients were applied to the lung sample, ring artifacts most prominent in the absorption contrast were eliminated. These improvements were due to the removal of ring artifacts for all contrasts and reduced cupping in absorption and phase images and reduced capping in visibility images.

The silicon sample created severe artifacts in all contrasts, but following correction, MSE was reduced by 94% in absorption, 96% in phase, and 90% in visibility images. The water sample's absorption CT image was most impacted by spectral artifacts, but following correction to decrease ring artifacts, an 80% reduction in MSE and 57% reduction in standard deviation was observed. Finally, the model developed using the water sample was applied to a fixated murine lung sample to demonstrate robustness for similar materials. Spectral artifacts such as cupping and ring artifacts were quantified using mean squared error (MSE) from the beam-hardening-free target image and standard deviation within a reconstructed image of the sample. The method's feasibility was demonstrated using a tabletop Talbot-Lau grating interferometer micro-computed tomography (CT) system using CT acquisitions of a water sample and a silicon sample, representing low and high atomic number materials. To account for the multicontrast nature of grating interferometry, this approach was extended to each contrast to obtain three sets of correction coefficients, which were determined empirically from a calibration scan. The proposed two-variable polynomial expansion strategy was inspired by work performed to address beam hardening from a primary modulator. The purpose of this work was to develop and validate a correction strategy for grating-based x-ray imaging that accounts for beam hardening generated from both the imaged object and the gratings. Consequently, the different energy dependencies of absorption, phase, and visibility contrasts impose challenges that so far have limited the achievable image quality. As a result, grating inhomogeneities due to manufacturing imperfections can cause spectral nonuniformity artifacts when used with polychromatic sources. However, these sources introduce beam hardening effects not only from the samples but also from the gratings. Talbot-Lau grating interferometry enables the use of polychromatic x-ray sources, extending the range of potential applications amenable to phase contrast imaging.

0 kommentar(er)

0 kommentar(er)